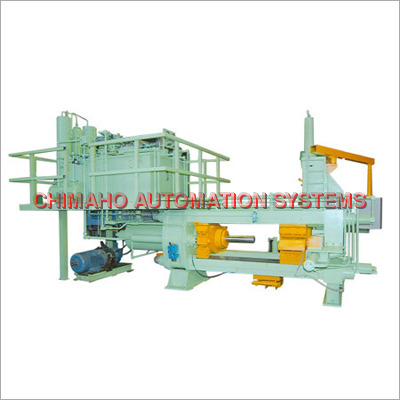

Forward Extrusion Press

MOQ : 1 Unit

Forward Extrusion Press Specification

- Operating Pressure

- Up to 250 bar

- Power Source

- Electric

- Application

- Metal Extrusion, Automotive Parts, Aluminium Profiles

- Mounting Type

- Floor Mounted

- Connectivity Type

- Wired Control

- Sealing Type

- Hydraulic Precision Seals

- Efficiency

- High (â¥90%)

- Temperature Range

- Ambient to 70°C

- Flow Rate

- Up to 500 L/min

- Accessories

- Die Set, Control Panel, Safety Guards

- Body Material

- High Grade Alloy Steel

- Type

- Forward Extrusion Press

- Structure

- Four Column Hydraulic

- Force

- Up to 4000 Ton

- Speed

- Variable, up to 20 mm/sec

- Voltage

- 415V AC, Three Phase

Forward Extrusion Press Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Cash on Delivery (COD), Delivery Point (DP), Letter of Credit (L/C), Letter of Credit at Sight (Sight L/C), Telegraphic Transfer (T/T), Western Union, Paypal, Cash Against Delivery (CAD), Days after Acceptance (DA), Cash in Advance (CID), Cheque, Cash Advance (CA)

- Supply Ability

- 1 Unit Per Month

- Delivery Time

- 1 Months

- Main Domestic Market

- All India

About Forward Extrusion Press

Inspired by the positive response given by our valued clients, we are engaged in manufacturing, supplying and exporting Forward Extrusion Press. Our offered machine is mainly used for extrusion of brass and aluminum section. We manufacture this machine using quality raw materials that are procured from certified vendors of the market. We offer this machine in different models and specifications in order to fulfill the needs of our patrons. Aided by our wide distribution channel, we deliver this Forward Extrusion Press at our clients’ destination within stipulated time frame.

Features:

- Excellent wear & tear resistant

- Rust proof

- Longer service life

- High material strength

Engineered for Peak Performance

Constructed from high-grade alloy steel and supported by a four-column hydraulic design, this press offers unmatched strength and durability for intensive extrusion tasks. Its sophisticated engineering enables precision and consistency, making it a preferred solution for manufacturers who demand high productivity and reliability from their machinery.

Advanced Hydraulic Technology

The press achieves forces up to 4000 tons and operates at pressures up to 250 bar and high flow rates. Hydraulic precision seals ensure leak-free operation, while variable speed controls allow for efficient adaptation to different materials and application needs. Its electrical system is powered by standard 415V AC three-phase connections for industrial compatibility.

Versatile Applications Across Industries

With its powerful performance and versatile accessory setincluding die sets and protective safety guardsthis forward extrusion press meets the demanding requirements of various sectors. It is highly suitable for manufacturing automotive components, aluminium profiles, and a wide range of metal extrusion products, making it an asset for exporters, manufacturers, and suppliers, particularly in India.

FAQs of Forward Extrusion Press:

Q: How does the four-column hydraulic structure of this extrusion press enhance stability?

A: The four-column hydraulic structure provides exceptional rigidity and even load distribution during the extrusion process, reducing flex and ensuring consistent quality in metal profiles and parts. This design contributes to machine durability and operational precision.Q: What safety features are included with the Forward Extrusion Press?

A: The press comes equipped with comprehensive safety guards and a control panel with emergency stop functions. These features ensure safe operation by minimizing exposure to moving parts and enabling immediate shutdown during emergencies.Q: When should maintenance be performed on this hydraulic press?

A: Regular maintenance should be scheduled according to the manufacturers guidelines, typically every six months or after a set number of operating hours. This helps ensure reliable performance, prolongs machine life, and sustains high efficiency.Q: Where can this extrusion press be installed, and what are its mounting requirements?

A: This press is designed for floor mounting in industrial environments. It requires a stable, level surface capable of supporting its weight and with access to a 415V AC, three-phase power supply. Proper ventilation and space for accessory installation must also be considered.Q: What is the typical process for metal extrusion using this forward extrusion press?

A: The process involves placing a heated metal billet into the press chamber, then applying high pressure (up to 4000 tons) through a die. The metal is extruded to form various shapes or profiles, suitable for applications in the automotive and construction industries.Q: How is variable speed beneficial in this extrusion press?

A: Variable speed, up to 20 mm/sec, allows the operator to adjust the pressing rate for different materials and products. This flexibility ensures optimal quality, minimizes waste, and increases overall efficiency in a range of extrusion tasks.Q: What advantages does hydraulic precision sealing provide in this press?

A: Hydraulic precision seals effectively prevent fluid leakage, maintain high pressure, and support smooth operation. This leads to improved energy efficiency, reduced maintenance costs, and longer equipment lifespan.

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS